Composite structures perform critical functions in an array of vital applications, such as Offshore Wind, Nuclear and Defence. The challenges of end of life management of composite structures is well documented e.g. 95% of WT blades going into land fill or being burnt. Other trends, such as the significant spike in global offshore investment places a demand on increased manufacturing throughput of blades without compromise on important certification standards. Other growing sectors include the #hydrogeneconomy with composite storage tanks being developed for decarbonisation of heavy transport (Innovatus Technologies Ltd). This will also experience significant growth given investments into accelerating decarbonisation as part of a global and integrated climate change response. Geopolitical factors are also promoting an increased self-reliance via storage solutions for the stability of national energy systems.

Sensing technologies are vital to our understanding of the characteristics and dynamics throughout the length scales (nm-to-metres) of such vital composite structures.

Therefore, we have published a detailed review of NDE sensing technologies for structural composite materials.

Thank you to our sponsors Innovate UK and MacTaggart Scott & Co Ltd. As well as the collaborative team from across Heriot-Watt University, Smart Systems Group and Robert Gordon University. Thank you also to MicroSense Technologies for their support in the collaborations with industry that have informed this review.

The paper Abstract is as follows:

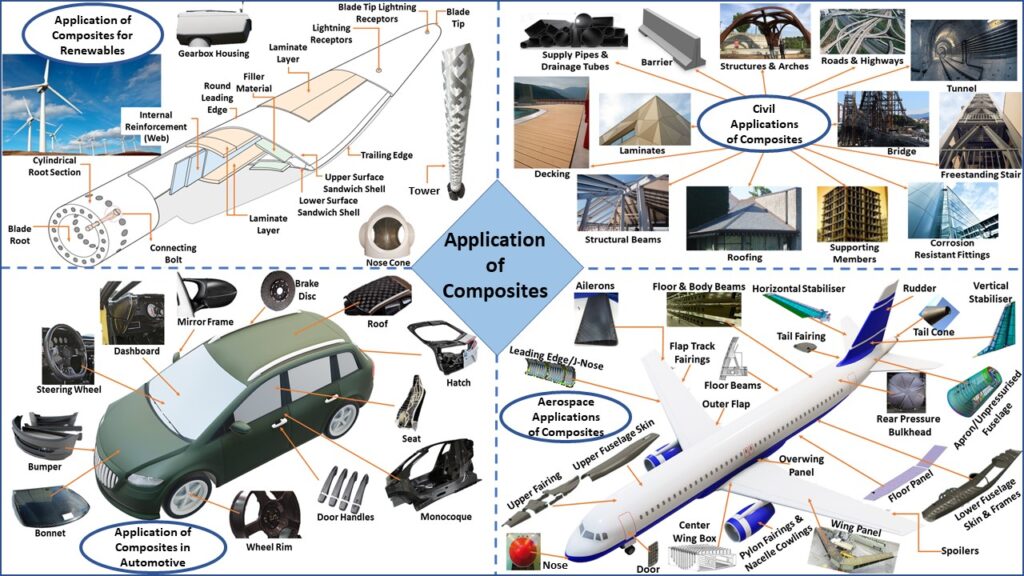

The growing demand and diversity in the application of industrial composites and the current inability of present non-destructive evaluation (NDE) methods to perform detailed inspection of these composites has motivated this comprehensive review of sensing technologies. NDE has the potential to be a versatile tool for maintaining composite structures deployed in hazardous and inaccessible areas, such as offshore wind farms and nuclear power plants. Therefore, the future composite solutions need to take into consideration the niche requirements of these high-value/critical applications. Composite materials are intrinsically complex due to their anisotropic and non-homogeneous characteristics. This presents a significant challenge for evaluation and the associated data analysis for NDEs. For example, the quality assurance, certification of composite structures, and early detection of the failure is complex due to the variability and tolerances involved in the composite manufacturing. Adapting existing NDE methods to detect and locate the defects at multiple length scales in the complex materials represents a significant challenge, resulting in a delayed and incorrect diagnosis of the structural health. This paper presents a comprehensive review of the NDE techniques, that includes a detailed discussion of their working principles, setup, advantages, limitations, and usage level for the structural composites. A comparison between these techniques is also presented, providing an insight into the future trends for composites’ prognostic and health management (PHM). Current research trends show the emergence of the non-contact-type NDE (including digital image correlation, infrared tomography, as well as disruptive frequency-modulated continuous wave techniques) for structural composites, and the reasons for their choice over the most popular contact-type (ultrasonic, acoustic, and piezoelectric testing) NDE methods is also discussed. The analysis of this new sensing modality for composites’ is presented within the context of the state-of-the-art and projected future requirements.

Full Paper can be read here: doi.org/10.3390/jcs5120319 : A Review of Sensing Technologies for Non-Destructive Evaluation of Structural Composite Materials