The Oil & Gas industry understands the potential of Artificial Intelligence (AI) and Big Data. However, contrary to AI consumer applications and many other industrial sectors, the dynamic and harsh environments of drilling and production operations as well as the global scale brings a very unique set of challenges for the deployment of industrialised, scalable AI.

To secure actionable insight from big data and for that to be transposed into automated AI decision support for operational and planning decision making, requires an integration of expert human knowledge on such complex systems such as drilling strings.

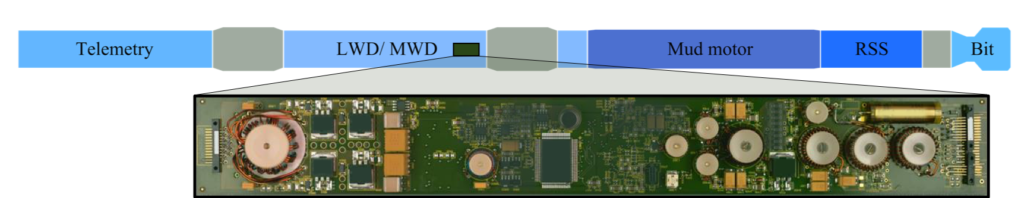

Heriot-Watt Universities Smart Systems Group (SSG) in cooperation with Baker Hughes actively addresses this challenge and provides a showcase on how AI and Data Analysis can transform downhole tool maintenance. The SSG researchers developed an AI-driven Condition Based Monitoring (CBM) pipeline, trained on Bottom Hole Assembly (BHA) memory data provided by Baker Hughes. Our approach achieved an accuracy of 90 % predicting BHA-PCBA failures. Data augmentation is used to increase the model’s robustness. To aid varying business needs, the methodology can be calibrated taking the health of the fleet and acceptable risk vectors into account.

The full Open-Access publication can be found here: 10.1109/ACCESS.2020.2990152